In respond to the demand for a higher data bandwidth, active optical cable (AOC) has came into being to satisfy different cloud computing applications. Active optical cable is a term used to describe a cable that mates with standard electrical interfaces. The electrical-to-optical conversion on the cable ends is adopted to enhance the transmission speed and distance of the cable without sacrificing compatibility of standard electrical interfaces. This article will give a general introduction of active optical cable and its most popular product in the current market.

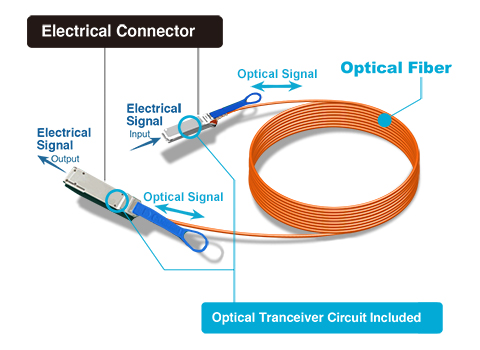

Structure of Active Optical Cable

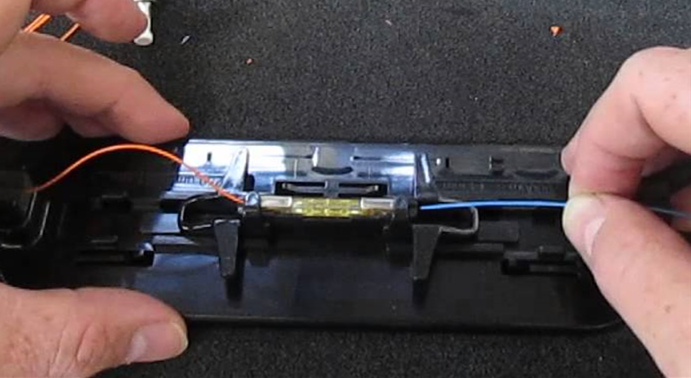

Active optical cable mainly consists of two parts- the fiber optic connector and fiber cable. The connection between fiber cable and connectors is not separable. If the connector or cable needs to be changed, they should be removed together. The electrical and optical signal conversion can be achieved right through each ends of optical fiber.

However, people may wonder the reasons why choosing active optical cable over direct attach copper cable. Here are some advantages of using active optical cable:

1) Although both cables are used for short range data communication, active optical cable is able to provide a longer reach than direct attach copper cable among devices.

2) Active optical cable has a higher bandwidth because its signal transmits through optical fiber as optical signal which transmits faster than electrical signal in copper cable. The maximum throughput is up to 40 Gbps with QSFP+.

3) The weight of active optical cable is lighter than copper cable due to the optical fiber material. It is possible to achieve a simpler cable management with a lower weight.

4) EMI (electromagnetic interference) immunity is another benefit of active optical fiber. EMI is a disturbance generated by an external source that affects an electrical circuit by electromagnetic induction, electrostatic coupling or conduction. Since the optical fiber is a kind of dielectric which is unable to conduct electric current, active optical cable will not be affected by the electromagnetic energy.

Applications of Active Optical Cable

Active optical cable has been applied to different fields. The followings are the most typical applications for active optical cables:

1) Infiniband QDR, DDR and SDR interconnects

2) Data aggregation, backplane and proprietary density applications

3) PCI-Express, SAS/SATA, Fiber Channel compatible interconnect

4) 40GBE and 10GBE interconnects

5) 10G, 40G telecom connections

6) Hubs, switches, routers, servers

7) Ethernet 10G, 40G

8) Data centers

9) High performance computing clusters

Popularity of 40G Active Optical Cable

Nowadays 40G active optical cable has become one of the most popular products in the market. It is an active optical cable used for 40 GbE terminated with 40GBASE QSFP+. Particularly, 40G breakout active optical cables, such as 40GBASE QSFP+ to 4xSFP+ AOC or 40GBASE QSFP+ to 8xLC AOC, are cost-effective solutions for 40G to 10G migration.

Conclusion

Active optical cable has now taken a great share of the market and is still booming for further development. The interconnection in short range and high speed between devices makes it practical in data center. As the technology matures, the application of active optical cable will be migrated to higher speed transmission in the future.

The article originates from http://www.chinacablesbuy.com/overview-of-active-optical-cable.html.