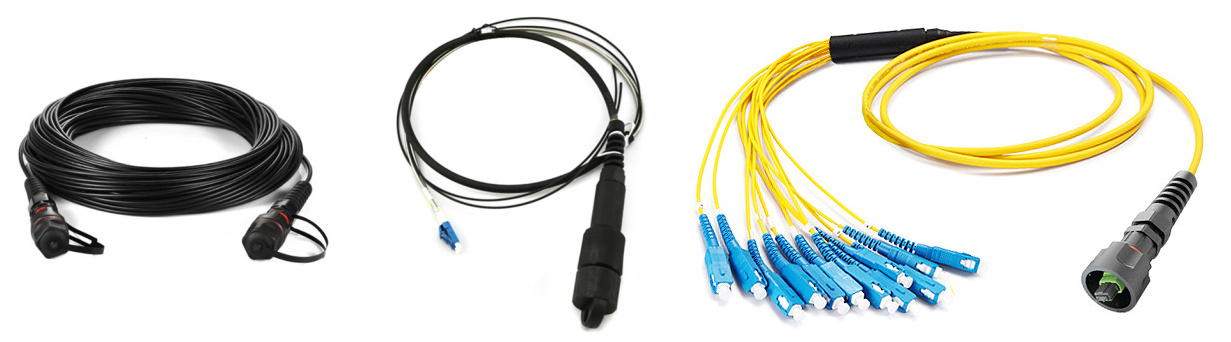

There are usually two ways for fiber optic termination. Bare optic fiber can be either spliced with another fiber for a permanent joint or connected with fiber optic connector for a temporary joint. When using the fiber optic connector, we can easily install or uninstall the cable for various applications. This type of termination is more flexible and simple to operate. It is also time-saving to use fiber optic connectors for cable connectivity. However, do you know the right process to terminate bare fiber with fiber optic connector? This article will guide you step by step.

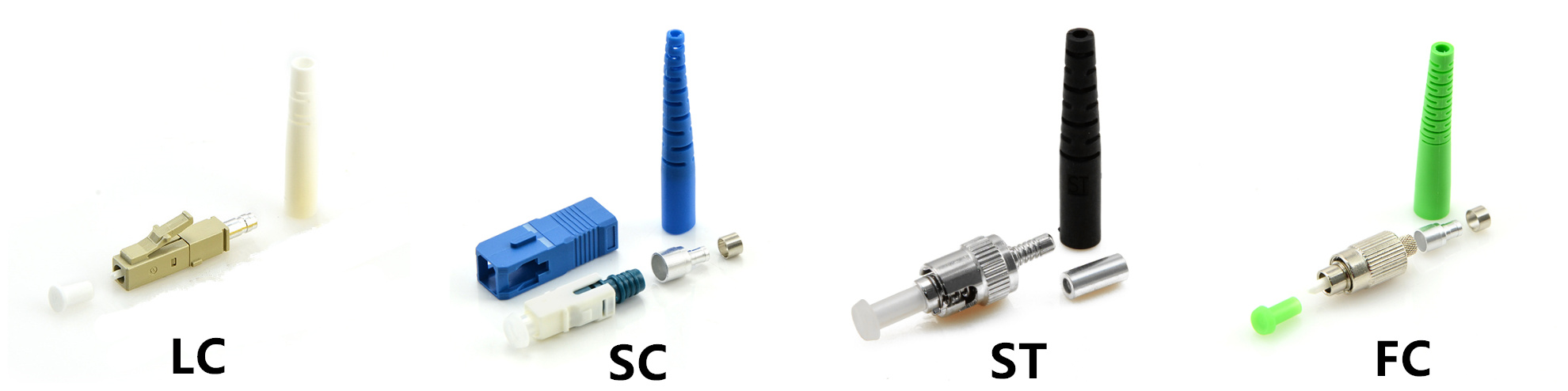

Common Fiber Optic Connectors

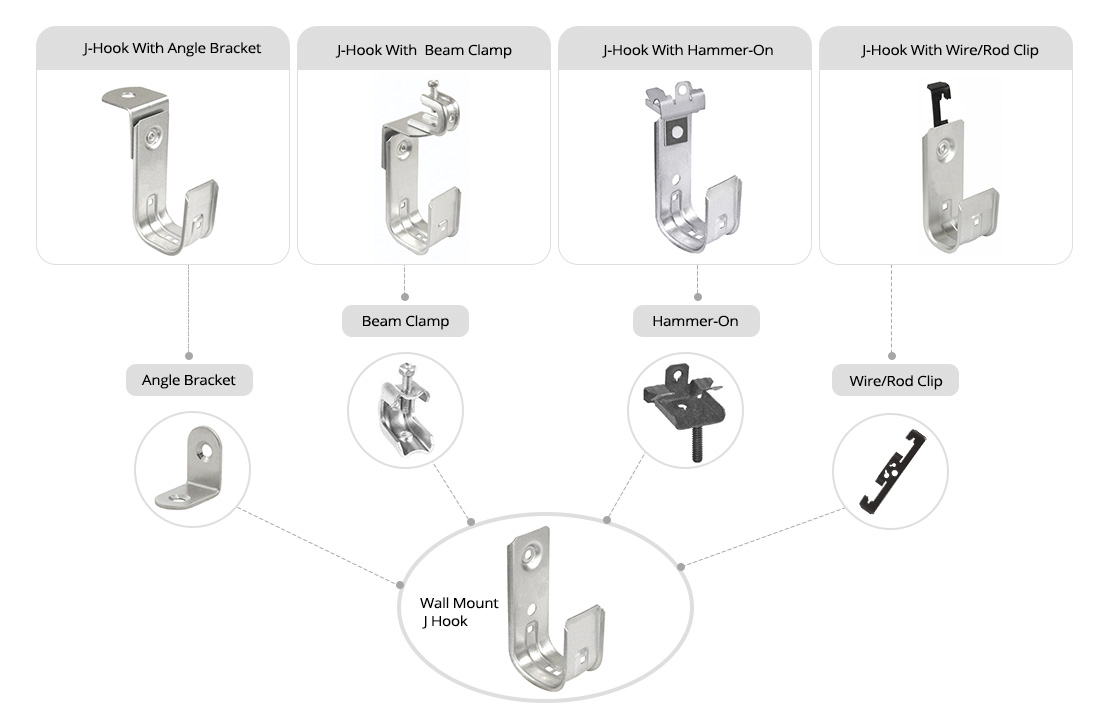

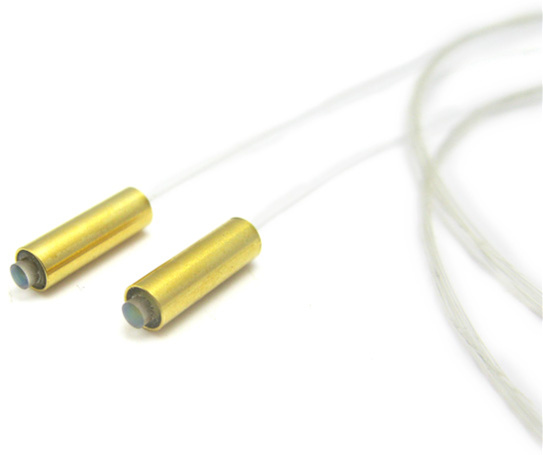

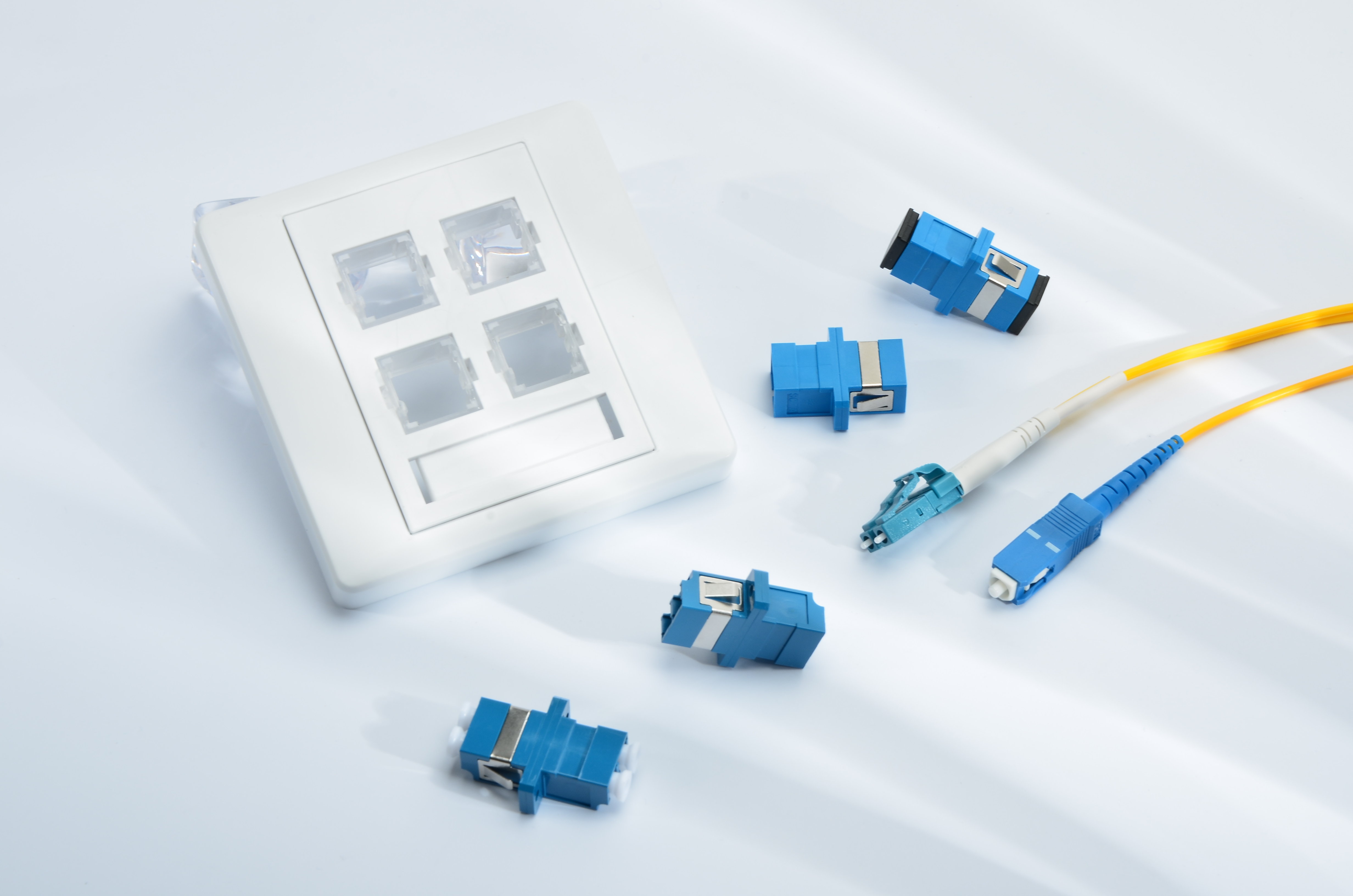

Let’s start from the fiber optic connectors. Choosing the right kind of connector for your termination is extremely important. In today’s market, four types of fiber optic connectors are widely used for terminating single fibers. They are LC, SC, ST and FC connectors. LC connector has a 1.25mm ceramic ferrule which is only half the size of other connectors. It’s a snap-in connector usually used for high-density applications. SC connector uses a 2.5mm ceramic ferrule and also features a snap-in connection for quick cable patching. Different from other connectors, ST connector uses a bayonet twist-lock connection with 2.5mm ferrule. Moreover, FC is a screw type connector with 2.5mm ferrule but is becoming less popular than LC and SC connectors.

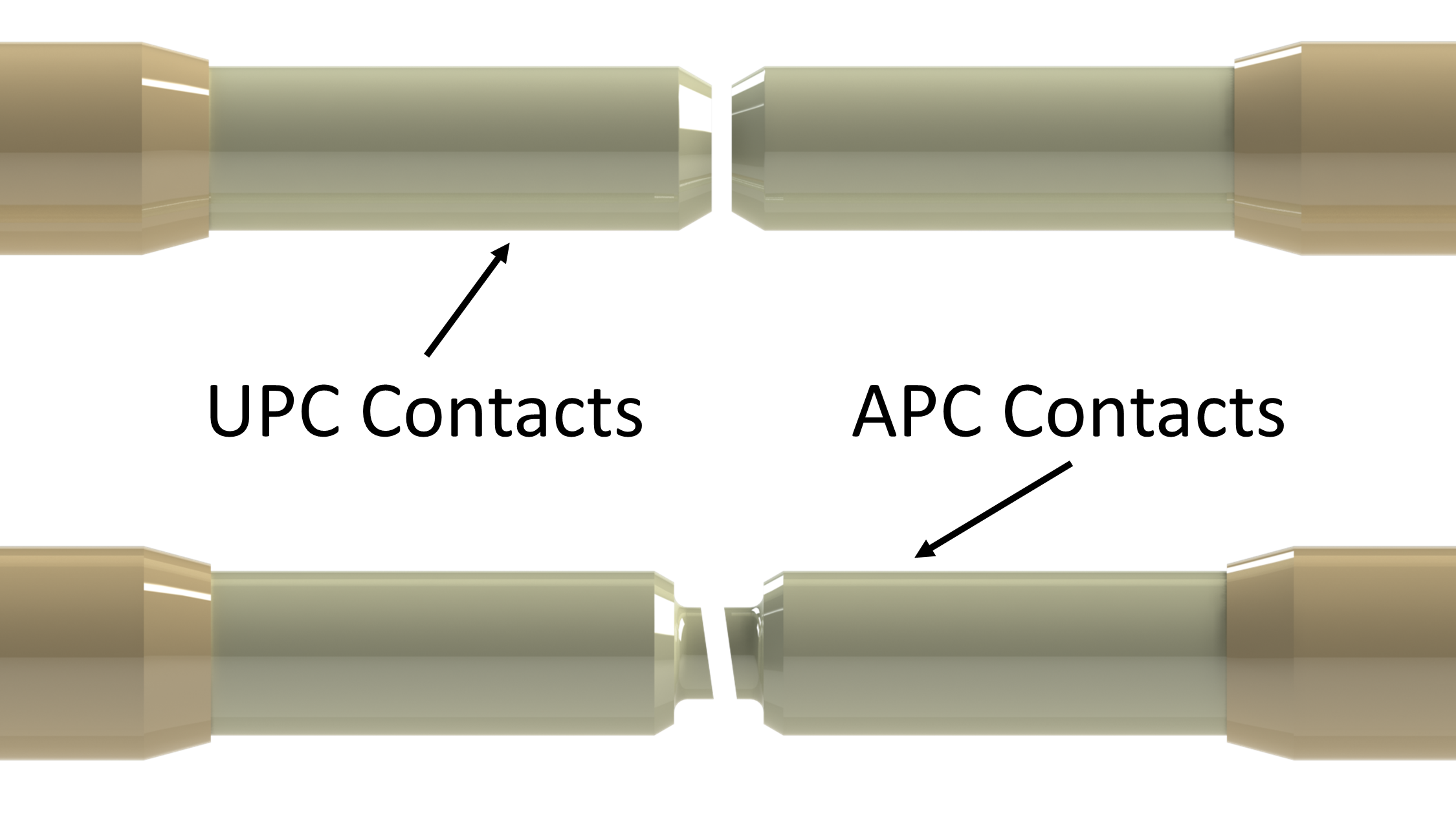

Connector Polish Styles

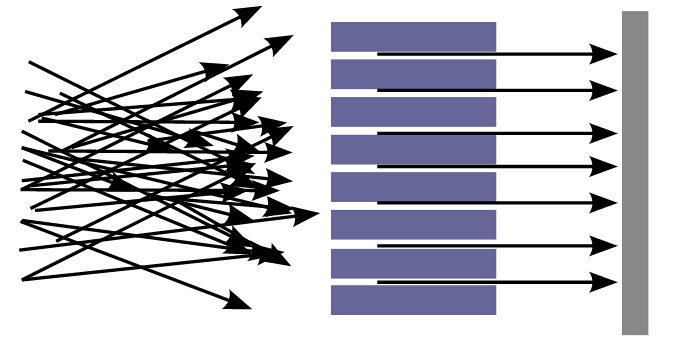

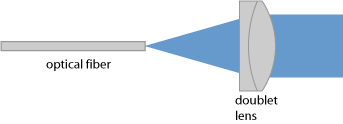

When terminating the optic fiber with connector, you should also decide the polish type if the connector is not polished in advance. Generally, connector end face will be polished to minimize back reflection of light. Using the mated polish styles, light can propagate through connectors with lower fiber loss. There are four types of polish styles - flat, PC, UPC and APC polishes. Among them, UPC and APC types are more popular in the industry. The major difference between UPC and APC connectors is that the APC type is polished at an 8-degree angle while UPC has no angle, but they are both slightly curved for better core alignment. As for the color, UPC connector is usually blue and APC connector is green.

Important Precautions

Fiber optic cable is very fragile and sensitive to contamination, thus we need to pay more attention to the precautions before starting termination. Here lists some general precautions as a reference:

- Always keep dust cap on unused connectors. Store spare dust caps in a dust free environment.

- Remember to clean the connector and fiber before termination.

- Make sure there is no laser light in the fiber during termination process.

- Do not bend the optic fiber at a radius less than 25 mm.

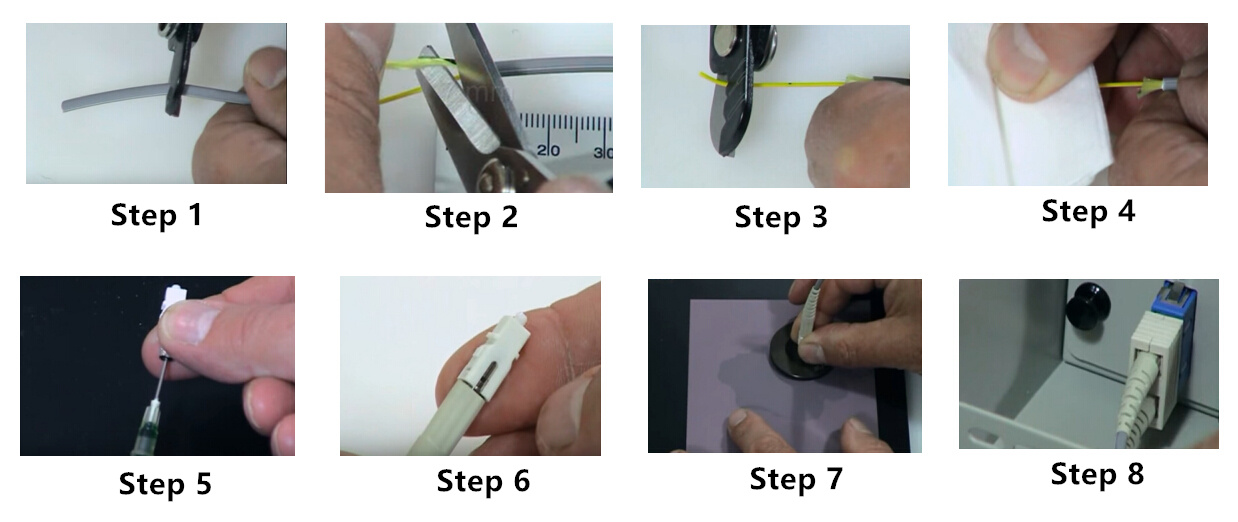

Termination Process

When everything is ready, we can begin the fiber optic termination. The followings are the specific steps.

- Step 1, measure and mark the cable jacket to the desired length(usually 35 mm). Place jacket stripper on mark and squeeze gently until cutter closes. Pull the cut section off the cable.

- Step 2, measure and mark kevlar to the desired length(usually remain 7 mm). Use scissors to cut away extra kevlar.

- Step 3, measure and mark the buffer to the desired length(usually remain 16 mm). Strip the buffer in several small lengths to avoid fiber damage.

- Step 4, use a lint-free, alcohol-soaked tissue to clean the fiber.

- Step 5, fill the syringe with adhesive, and slowly inject the adhesive into the ceramic tip.

- Step 6, gently insert the fiber into the connector and put the connector components together.

- Step 7, place the connector in the polishing disk. Put it on the polishing film, and lightly polish the connector for 8 to 10 times.

- Step 8, mission complete! Give it a try on your equipment.

Conclusion

Bare fiber terminated with fiber optic connectors greatly eases the stress for cable installation. It is always recommended to turn to the professionals for help when doing fiber optic termination.