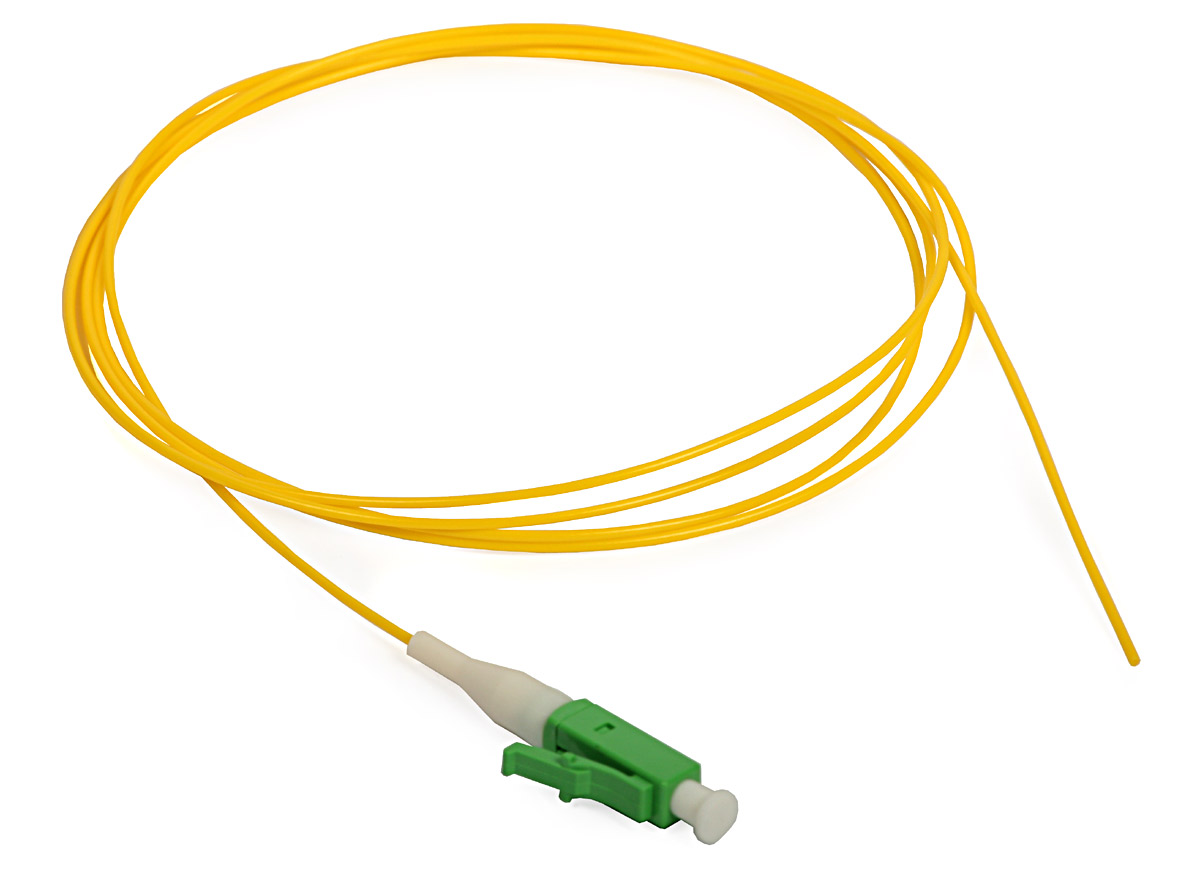

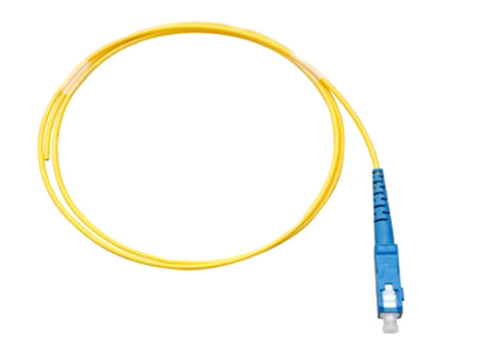

With the development of telecommunication, demands for fiber patch cables are increasing all over the world. However, it is known to all that cables under harsh environment must be in need of better protection. Luckily, the advent of armored fiber patch cable efficiently solves the problem. As the name indicates, this type of optical cable is wrapped in a protective armor to prevent optical cables from animal bite, moisture, corrosion and other damage. Therefore, using armored fiber optic cable will greatly reduce the cost of unnecessary cable loss. This article will give you a basic introduction about the structure, types and advantages of armored optical cable.

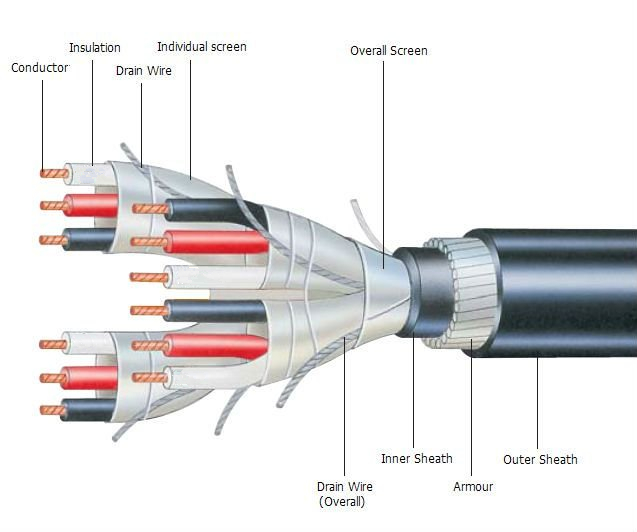

Structure of Armored Fiber Optic Cable

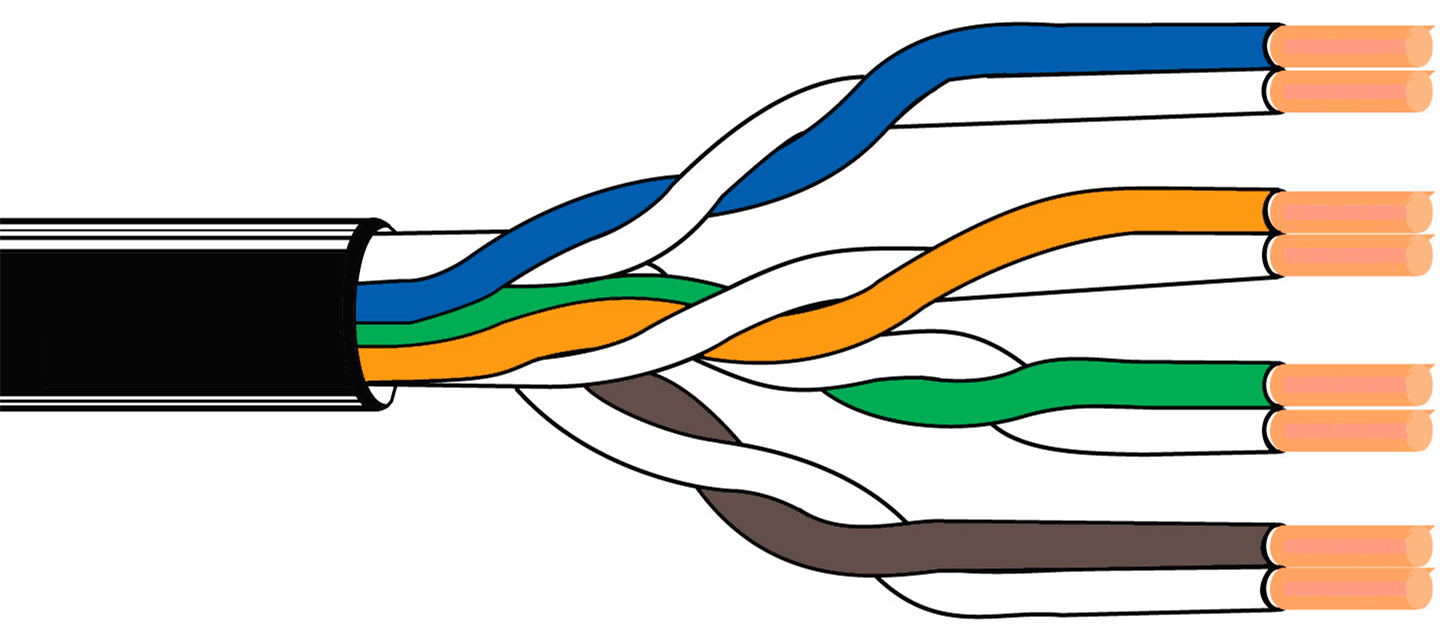

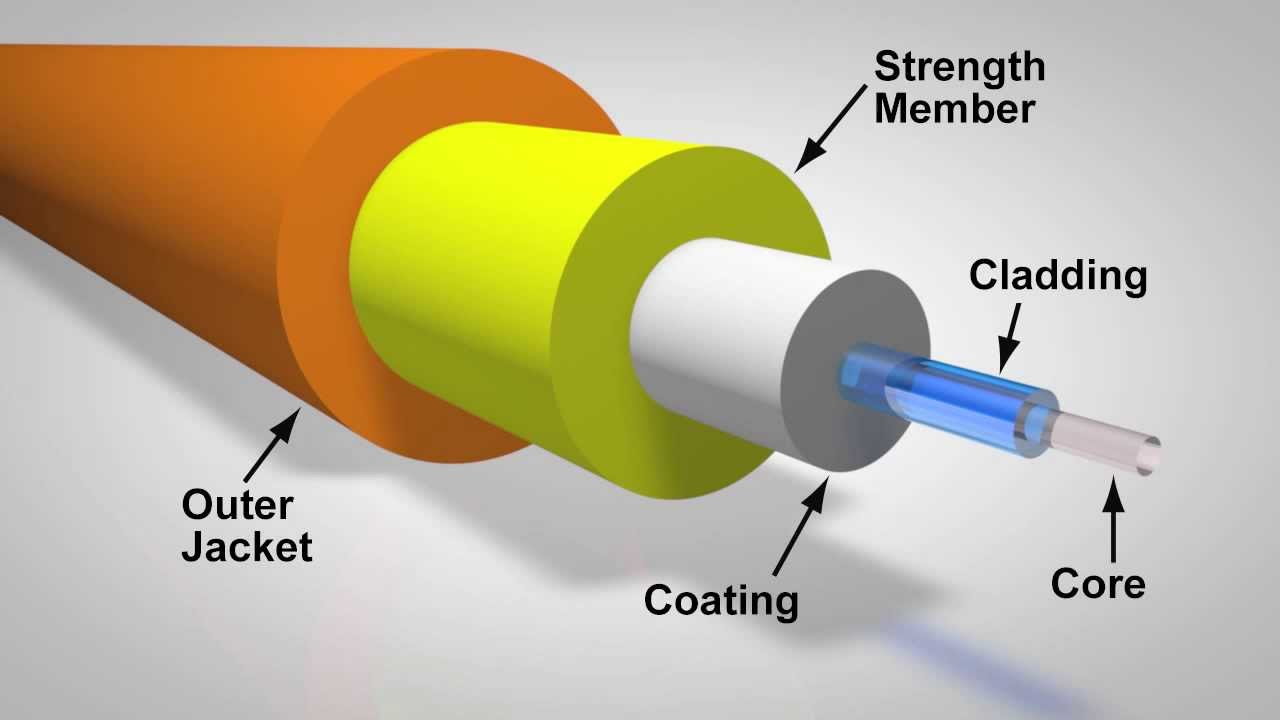

Armored fiber optic cable has some basic layers. The first layer is the outer jacket made of plastic materials. It can protect the cable from the destroy of solvent and abrasion. The second layer under outer jacket is the strength member made of armored materials, such as aluminum foil, steel and kevlar. These materials are difficult to cut, bite and burn which are great protections for the optical cable. Next is the inner jacket of fiber made of protective and flame-retardant materials to support the internal optical fibers.

Types of Armored Fiber Optic Cable

Armored fiber optic cable can be divided into indoor armored optical cable and outdoor armored optical cable according to the premises.

Indoor Armored Optical Cable

This kind of optical cable includes double and single indoor armored fiber patch cables. The double armored cable has the stainless steel wire woven and stainless steel tube. On the contrary, the single armored cable does not contain the stainless steel components. Most of the indoor armored cables are deployed for building wiring applications. You may find them in walls, between floors, in plenum air handling ducts and under data center floors, etc.

Outdoor Armored Optical Cable

There are light armored and heavy armored optical cable used for outdoor applications. The light armored cable has the protective plastic jacket with the same durability and longevity of a stainless steel cable, but its weight is much lighter. The heavy armored cable is wrapped in a wire circle which can be applied for riverbed and ocean floor.

Advantages of Armored Fiber Optic Cable

There are numerous advantages of armored fiber optic cable. The flexibility and durability of armored cable are excellent which makes it the right choice for industrial purposes. Moreover, the armor materials protect the cable from damage caused by animal, human or harsh environment, thus it can be applied to places where ordinary cables can not. The armored cable can also undergo heat and high pressure of extreme conditions. Using the armored optical cable not only ensures the high speed data transmission, but also extends the life span of cables.

Conclusion

When fiber optic cables are needed for terrible conditions, a strong protection for the cable is very necessary. Therefore, to secure the data communication, armored fiber optic cable is a good solution to make the cable free from different damages. But when you operate the armored cables, you must be careful of the freshly cut edges which are very sharp to cope with. And the budget of your project should also be taken into consideration as armored cables are generally more expensive than the common ones.