When you first saw a cable tie, you might feel nothing special about it. It’s just a tie for holding cables together, what more could it be? But the fact is that if you want to completely get rid of messy cables, cable ties are of great importance. They are generally inexpensive, and can be ordered in various colors and sizes. There are many types of cable ties on the market. Different types are made for various applications. Using the right cable tie can speed up your working efficiency. This article will introduce some common cable tie solutions. Maybe one of them is perfect for your project.

Self-locking Cable Tie

Self-locking cable tie has the classical oval lock structure for easy installation. It is the most common cable tie consisting of a flexible nylon tape with an integrated gear rack, and on one end a ratchet within a small open case. With a good locking design, cable tie can provide firm locking for the cables. This kind of cable tie is shorter and thinner for small spaces and light wire management. Its curved tip is easy to pick up from flat surfaces and allows faster initial threading to speed installation.

Stainless Steel Cable Tie

Stainless steel cable tie is used when there is liquid involved and when extreme temperatures are involved. This cable tie can withstand temperature ranging from -100 to +1000 degrees Fahrenheit. The stainless steel cable tie has a tensile strength of 100 lbs. And it has the capability to endure most chemicals that will cause corrosion. It can be used for the most extreme environment or where additional strength, security and fire resistance are required.

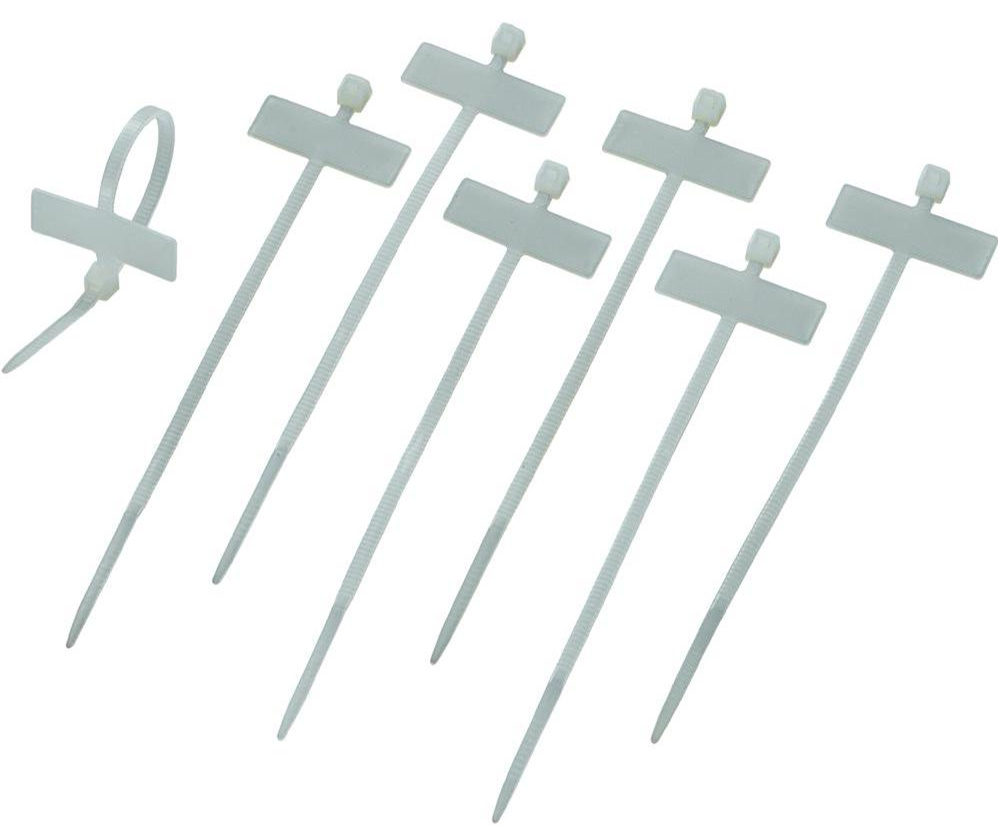

ID Marker Cable Tie

ID marker cable tie or identification cable tie features a large marker area for the imprinting or handwriting of cable assembly numbers and other vital information, making cable and wire identification in an extensive range of applications a fast and easy task. Whenever cable colors are not enough for cable identification, ID marker cable tie plays a part.

Mount Head Cable Tie

Mount head cable tie combines the zip tie and mounting eyelet together. It allows you to bundle cables and then mount them to a surface using screws, nails, clamps or clips. Surfaces including walls, ceilings, server racks, trailers, vehicle chassis, and other areas are able to handle the cables easily with mount head cable tie.

Releasable/Reusable Cable Tie

Releasable cable tie is actually reusable nylon self-locking cable tie. The common nylon cable tie can only be used once. If you need to re-bundle or rearrange the cables, then releasable cable tie is your best choice. By pressing the latch on the tough of cable tie, it can be easily released from the cables.

Velcro Cable Tie

Velcro cable tie or hook and loop cable tie is made of a self-attaching hook and loop material. It is reusable and adjustable to support frequent moves, adds, and changes of cables. Usually sold in rolls, velcro cable tie can be easily cut down to any length you want. No matter for factory devices or household appliance, velcro cable tie is very convenient to be used for cable management. It also has many other types with different shapes such as the T type velcro cable tie, the voltage type velcro cable tie and the buckle velcro cable tie.

Conclusion

Cable management is especially essential for device installations where large amount of cables are needed. As a cost-effective tool, cable tie can be simply mounted to arrange the cable mess which enables higher performance of devices. The above options are some common types in the market. You should choose the right cable tie according to your actual application.